Web Considerations for Today’s Flexible Packaging

Time:2021-05-28 From:

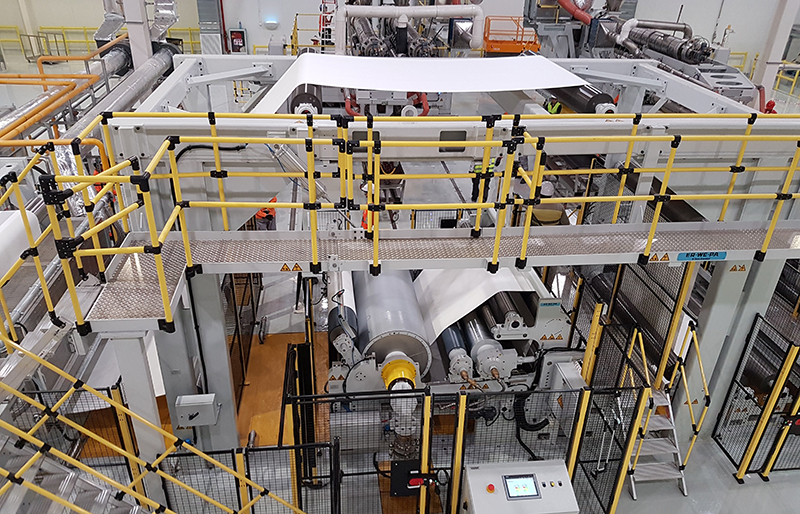

Maximizing the productivity, versatility and profitability of an extrusion coating and laminating line is the goal of every flexible packaging film producer. Production lines that process films for food, industrial and consumer applications must be equipped to handle lighter gauge materials. Machinery must also address diverse multi-layer structures at higher production speeds without scratching and/or wrinkling defects. Web tension control systems and web handling components are a key part of achieving desired results. Factors such as the location of web tension control zones, the type of support rollers and bearings used, and web spreading parameters are paramount. It is also important to correctly apply web guidance in coating, laminating and winding processes.

Technical advancements in flexible packaging materials have enabled thinner webs to be processed with the same or greater strength and barrier properties. Physics states that the resistance of webs to buckle (wrinkle) is a function of the cube of web thickness. Therefore, reducing the gauge by 10 percent makes the web almost 1.4 times more prone to wrinkling. Thinner webs must be run at lighter tensions and with precision tension control to prevent wrinkling and distortion effects. These materials can also run at higher speeds, but greater care must be given in maintaining positive traction with web conveyance and guidance rollers.

Following are some engineering considerations with regard to precision tension control, web spreading and web guidance as you seek to produce thinner webs at higher speeds.

Precision tension control

Flexible packaging lines need to have positive isolation between unwinding, process and winding zones to achieve optimal tension control. Good tension isolation requires a driven pull roll section with a positive grip of the web between these zones. Precision tension control requires dependable and correctly positioned load transducers in each zone. Exacting tension also demands well-designed web handling rollers. Rollers need to have low-friction bearings, effective traction surfaces, correct spacing and web wraps, and proper alignment to ensure positive conveyance of webs at the required lighter tensions. Well-designed web handling rollers will also help eliminate uncontrollable web tension and/or scratches. Using pre-set recipes in an integrated control system allows for consistent and repeatable tension programmed by zone.

Dry bond lamination lines are an example of how web tension is critical to avoid defects. Before the lamination process, the web materials need to be properly tensioned to closely match the strains of the materials just before lamination. Failure to do so can result in a delamination defect commonly known as tunneling. Tunneling is common on aseptic packaging and transdermal patch production lines.

Web spreading

Web spreading devices before the nips, before critical processes such as coating and laminating, and just before winding are mandatory for high-quality processes. Using the right type of web spreader in each of these areas is imperative, especially for high-speed production of thinner packaging materials. Multiple web spreader designs exist, so make your selection based on the types of structures you process for best results. Spreaders need to be well-maintained and adjusted for consistency.

Web guiding

Edge sensor guiding offers several production advantages in terms of performance and versatility. This technology positions incoming webs to compensate for potential telescoping of incoming rolls of materal; guides webs after the coating and drying process; guides webs into a lamination process; and ensures winding of straight-sided rolls. It also can provide web oscillation to help randomize web profile defects in wound rolls.

Unwinds can be mounted on a side-lay base or used as an offset pivot guide (OPG) to steer the web into the extrusion coating process. OPGs are needed before critical edge position lamination processes. A steering guide is required after long web leads such as out of a floatation dryer. An OPG can guide a web into the winding operation or the winder can be guided to the incoming web. The type of web guiding system, sensor, and location should be engineered for the application. Traction should be sustained on the roll just before or after the edge sensor, and the sensor needs to be mounted as close to the roll as possible.

In conclusion, web conveyance design and optimization is a critical tool for any flexible packaging film producer to increase line speeds, reduce defects, improve uptime dependability, and produce a wider range of structures.